Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

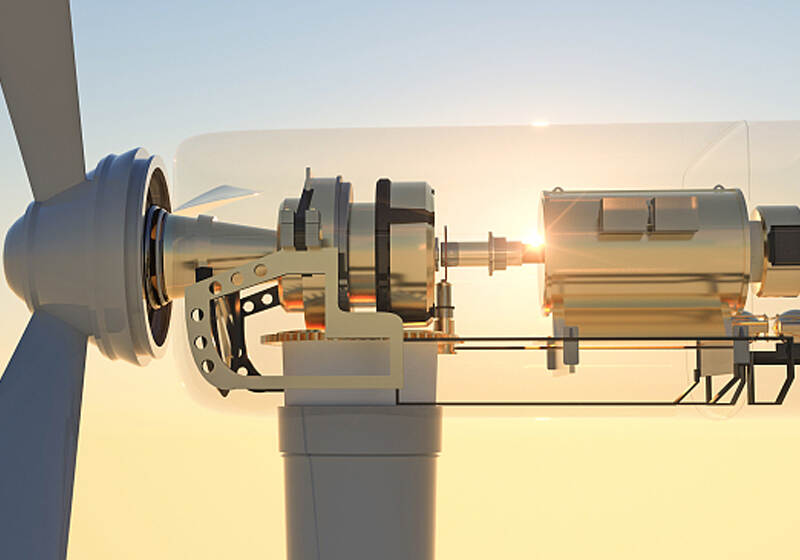

Configuration of wind turbine bearings

Configuration of wind turbine bearings

First, the current power level of wind turbine has exceeded 3MW. bearings should bear moderately high load, suitable for vibration and vibration conditions. Low friction standard rolling bearings are suitable for wind turbines. The bearings are mounted on standard or special bearing housings. In special cases, special rolling bearings can also be used. Rolling bearings used in wind turbines often need to meet high quality requirements.

Secondly, the main bearing configuration can be in the form of a main bearing configuration or a hub bearing configuration. There are successful examples of spherical roller bearings, cylindrical roller bearings or tapered roller bearings in fixed/floating terminal bearing configurations.

Third, in a hub bearing arrangement, two tapered roller bearings can be adjusted to each other. Another option is to use a pair of tapered roller bearings as the fixed end and a pair of cylindrical roller bearings as the floating end. The design of a single bearing should select multiple rows of rolling bearings to carry both force and torque. When the blade is adjusted, a small rotational motion is carried out under a large load and hegemonic torque, and a 4-point contact ball bearing is usually chosen to support it.

Fourth, as yaw bearings, four-point contact ball bearings should bear large gravity and wind loads. In wind turbine gearbox, all rolling bearing types available for gearbox structure are usually available.