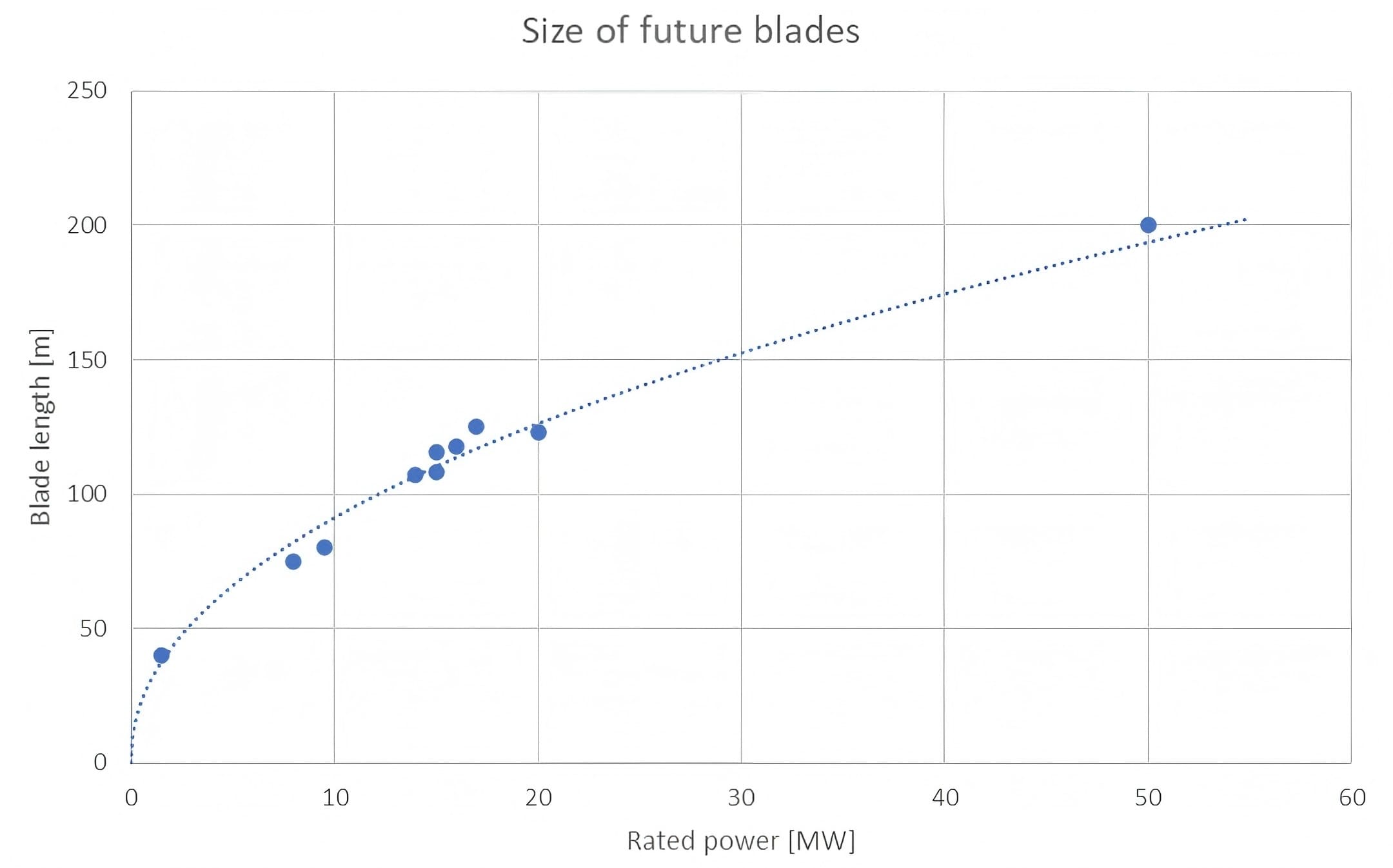

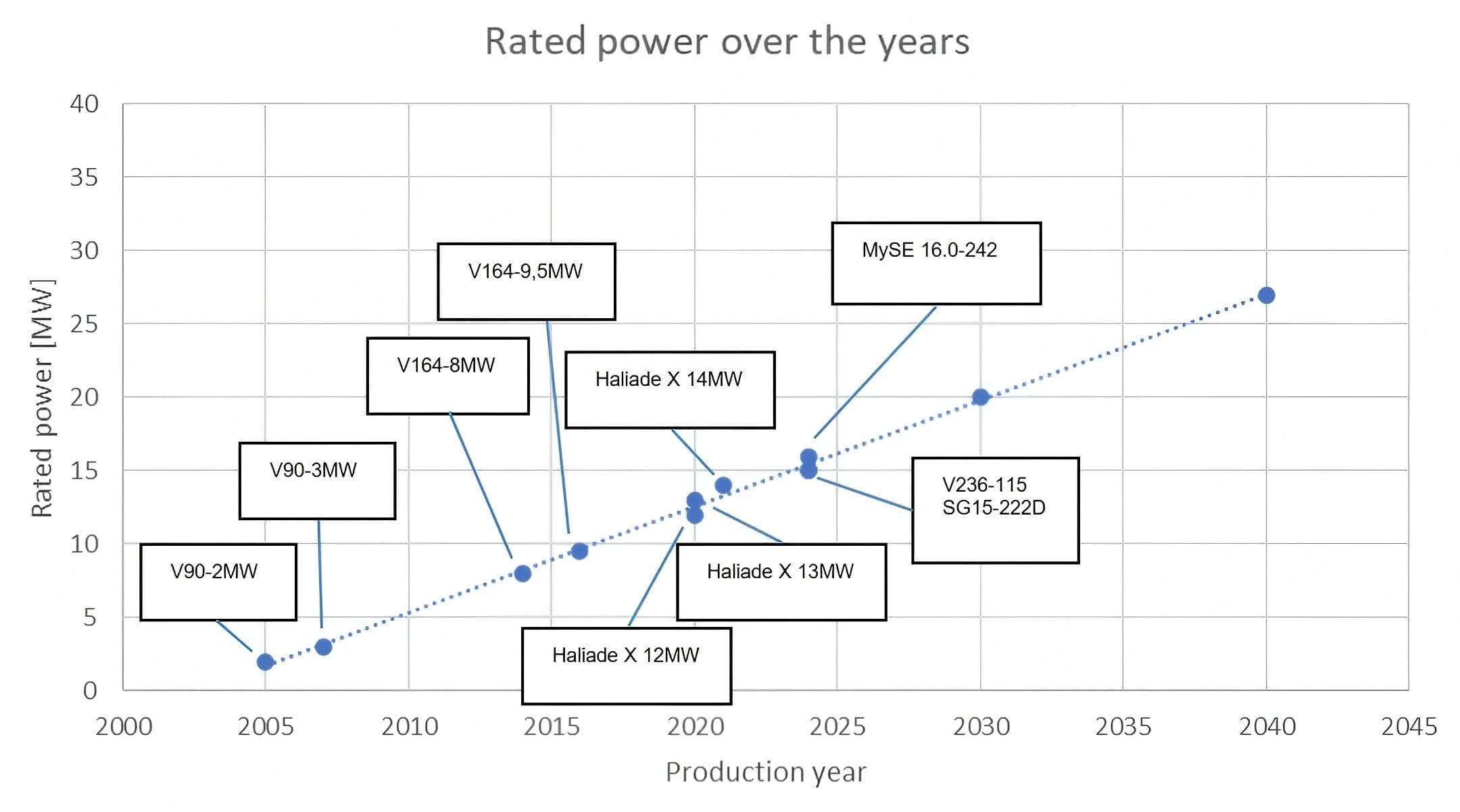

In recent years, wind turbine blades have been caught in an arms race of “who is bigger” and the newly released blades are longer and longer. There is no doubt that according to the load limit of composite materials, there is a limit to the length of blades. Perhaps 15 years later in 2040, the maximum length of blades will no longer increase, and this world record will be maintained forever until a material with better performance than carbon fiber appears.

Are you curious about what the blades will look like in 2040? TNO Laboratory in the Netherlands has given their answer.

Details

Based on the relevant data of wind turbines currently available, it is estimated that by 2040, the rated power of wind turbines will remain at 27 MW, corresponding to a blade length of approximately 145 m.

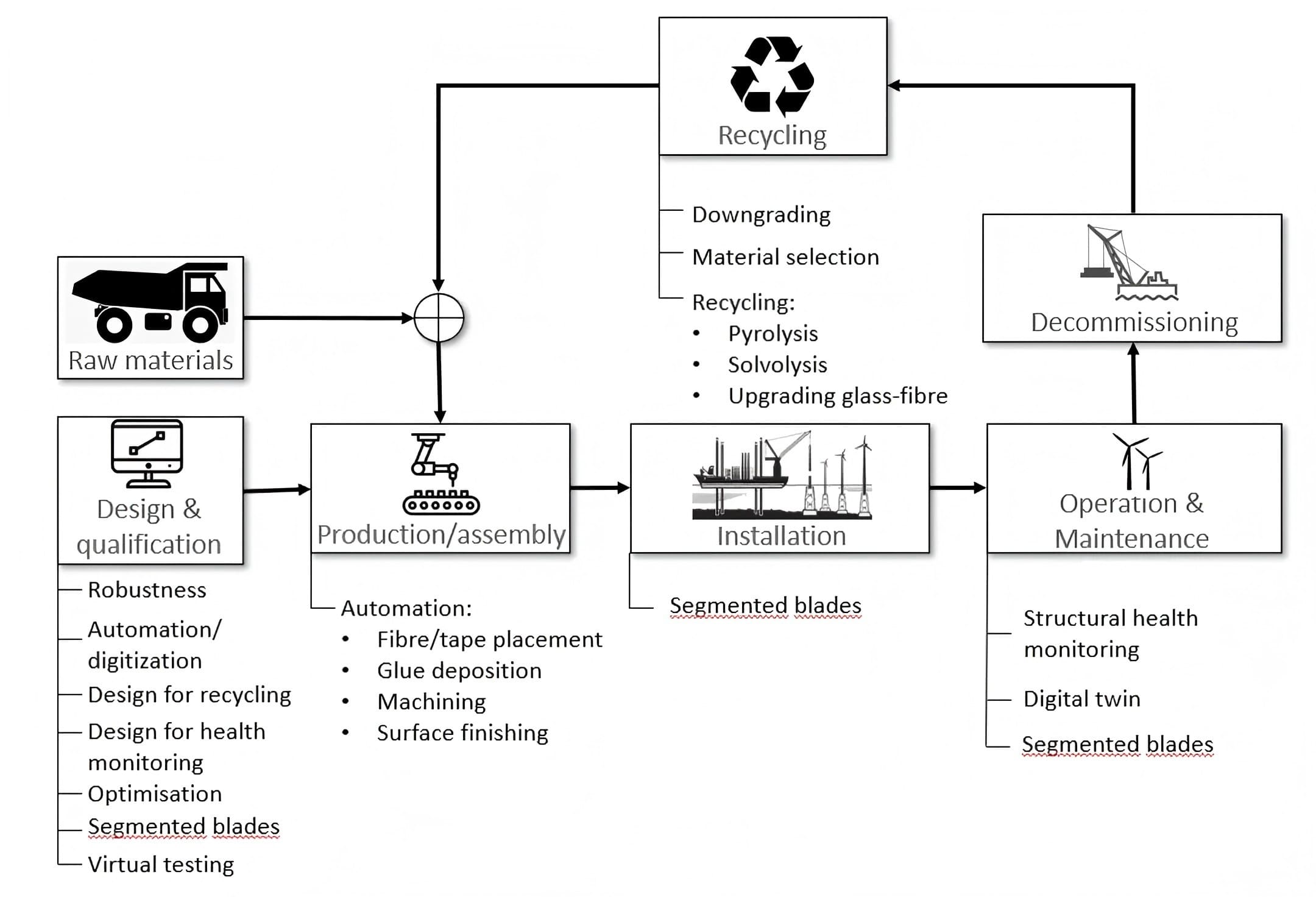

In the entire life cycle of the blade, which includes six core links such as design, manufacturing, installation, operation and maintenance, decommissioning and recycling, the blades of 2040 have many differences from traditional blades in the past.

Design

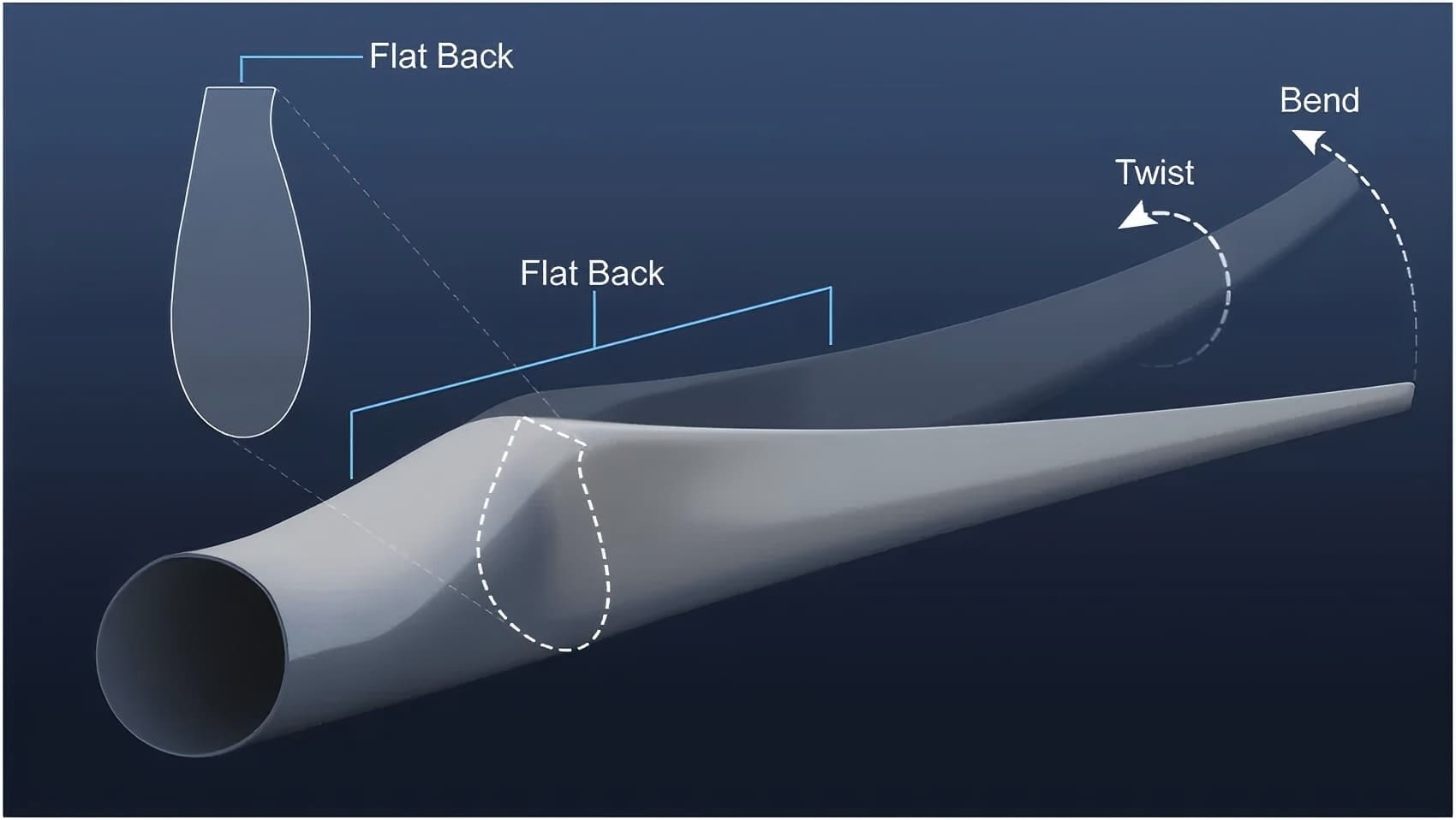

1) Aeroelastic optimization: Bending-torsion coupling technology will improve blade stiffness and boost structural reliability for next-generation blades.

2) Segmented design: Future blades will likely use segmented designs. This simplifies transport and reduces loads on blades and equipment.

3) Overall optimization design: Blade design will balance aeroelastic traits with strength, durability, surface wear, and lifespan. Segment location and joining tech will be key.

Manufacturing

- Automated Production: Blade production will shift to automated methods like 3D printing and automatic tape laying. These raise quality and cut errors.

- New Materials: Thermoplastics, bio-resins, and liquid crystal polymers will support zero-waste and fully recyclable blade manufacturing.

Installation

Large blades may face extreme loads during transport or setup—far beyond normal designs. Engineers will develop special tools to manage these stresses and eliminate the need for costly overdesign.

Testing

Virtual Testing: Numerical simulations will combine all uncertainties to test blade reliability. This speeds up design, cuts costs, and eases certification.

Operation and maintenance

- Structural Monitoring: Sensors and digital twins will monitor blades in real time. They’ll predict wear, optimize maintenance, and reduce downtime.

- Smart Control Systems: By using local weather data and market info, blades can adjust operation and maintenance strategies dynamically.

Recycling

Recyclable Design: Blade designs will focus on reuse. Polymers with reversible chemistry may replace today’s thermosets to allow full material recovery.

—

Note: Many of these technologies—segmentation, aeroelastic coupling, recyclable resins, and virtual testing—have existed for over 20 years. But despite frequent mention, few have seen large-scale use. Hopefully, by 2040, they’ll become standard across the industry.